Apparently, folks in the material science world are totally over the fact that we’re able to 3D print titanium alloys willy-nilly.

Because they have exceptional strength-to-weight ratios, corrosion resistance, and biocompatibility, titanium alloys are used to make aircraft frames, jet engine parts, hip and knee replacements, dental implants, ship hulls, and golf clubs.

Ryan Brooke, an additive manufacturing researcher at Australia’s RMIT University, believes we can do way better. “3D printing allows faster, less wasteful and more tailorable production yet we’re still relying on legacy alloys like Ti-6Al-4V that doesn’t allow full capitalization of this potential,” he says. “It’s like we’ve created an airplane and are still just driving it around the streets.”

Ti-6Al-4V is also known as Titanium alloy 6-4 or grade 5 titanium, and is a combination of aluminum and vanadium. It’s strong, rigid, and highly fatigue resistant. However, 3D-printed Ti-6Al-4V has a propensity for columnar grains, which means that parts made from this material can be strong in one direction but weak or inconsistent in others – and therefore may need alloying with other elements to correct this.

To be fair, Brooke is putting his money where his mouth is. He’s authored a paper that appeared in Nature this month on a new approach to finding a reliable way to predict the grain structure of metals made using additive manufacturing, and thereby guide the design of new high-performance alloys we can 3D print.

The researchers’ approach, which has been in the works for the last three years, evaluated three key parameters in predicting the grain structure of alloys to determine whether an additive manufacturing recipe would yield a good alloy:

- Non-equilibrium solidification range(ΔTs): the temperature range over which the metal solidifies under non-equilibrium conditions.

- Growth restriction factor (Q): the initial rate at which constitutional supercooling develops at the very beginning of solidification.

- Constitutional supercooling parameter (P): the overall potential for new grains to nucleate and grow throughout the solidification process, rather than just at the very beginning.

Through this work, the team experimentally verified that P is the most reliable parameter for guiding the selection of alloying elements in 3D-printed alloys to achieve desired grain structures for strength and durability.

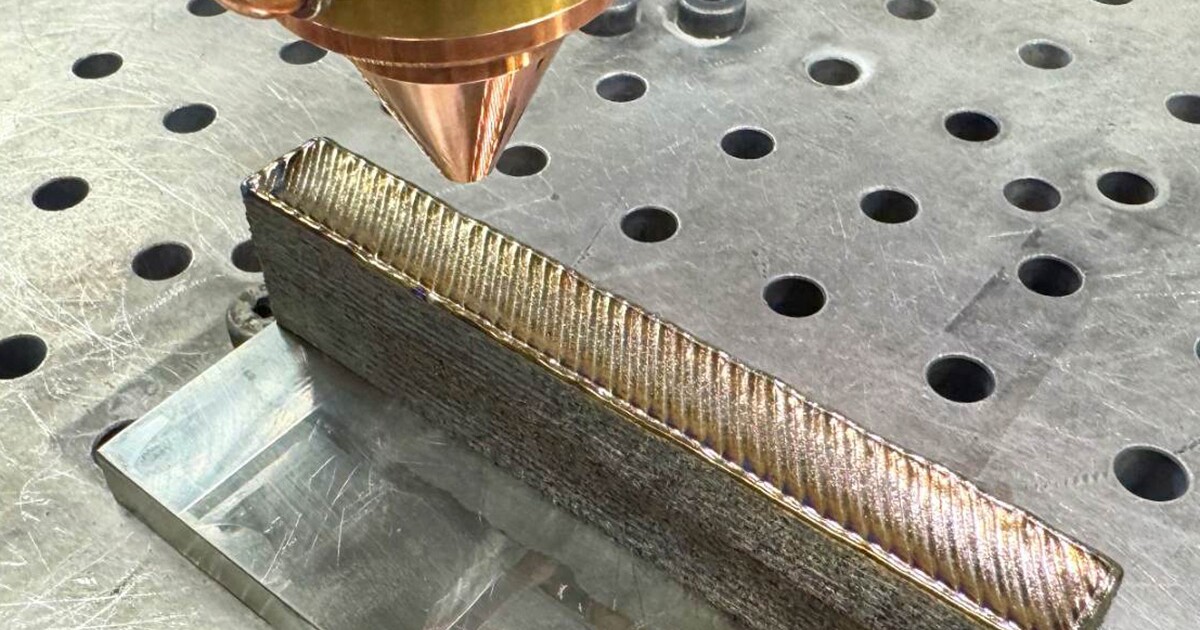

Image courtesy of the researchers

This method, which uses a wealth of experimental data and computational tools, is said to save on time and costs in developing additively manufactured alloys by reducing the number of iterations and speeding up development cycles.

The team didn’t describe its own titanium alloy in the paper as it plans to commercialize it soon – but claims it’s 29% cheaper to produce than regular titanium. The researchers also noted that they “have been able to not only produce titanium alloys with a uniform grain structure, but with reduced costs, while also making it stronger and more ductile.”

That could make titanium alloy more accessible for the aforementioned applications across industries ranging from aerospace to healthcare, and potentially lower the costs of manufacturing and maintaining high-performance components.

Source: RMIT University