Comprehending process optimization is essential for any organization aiming to improve efficiency and reduce waste. By analyzing and refining business processes, you can streamline operations and boost productivity. Techniques like process mapping and root-cause analysis play a key role in this expedition. As you explore the steps involved in effective process optimization, you’ll discover how to implement changes that drive results. What challenges might you face in this endeavor, and how can you overcome them?

Key Takeaways

- Process optimization is a systematic approach to enhancing business processes by reducing waste and inefficiencies.

- Key techniques include process mapping, data analysis, and root-cause analysis to identify improvement areas.

- Establishing clear objectives helps streamline operations and maximize resource utilization for better outcomes.

- Continuous monitoring of processes with Key Performance Indicators (KPIs) supports ongoing improvement and adaptation.

- Addressing challenges like resistance to change and limited resources is crucial for successful implementation of optimization efforts.

What Is Process Optimization?

Process optimization is a systematic method that organizations use to analyze and improve their business processes, ensuring they achieve maximum efficiency and quality.

Comprehending process optimization meaning involves recognizing its role in industrial process optimization, which focuses on continuous improvement. This approach seeks to reduce waste and inefficiencies as well as maximizing resource utilization.

Key techniques include process mapping to visualize workflows, data analysis using key performance indicators (KPIs) to measure success, and root-cause analysis to identify areas needing improvement.

By streamlining operations and enhancing productivity, organizations can’t only reduce costs but additionally boost customer satisfaction through higher quality products and services.

Effective communication and stakeholder involvement are crucial to align these efforts with business objectives and cultivate a culture of continuous improvement.

The Importance of Process Optimization

Comprehending the significance of process optimization is vital for organizations endeavoring to remain competitive in today’s fast-paced market. By streamlining operations, you can improve efficiency and enhance client satisfaction, as 75% of businesses have experienced.

Here are some key benefits of process optimization:

- Reduces waste and increases productivity

- Improves overall operational effectiveness

- Enhances quality standards and client satisfaction

- Cultivates a culture of continuous improvement and innovation

Engaging in systematic process optimization allows your organization to achieve greater throughput and cost savings, greatly impacting performance and profitability.

Objectives of Process Optimization

Optimizing business operations is essential for achieving specific objectives that can drive an organization toward success. The primary goal of process optimization is to streamline operations, ensuring you maximize resource utilization as well as minimizing waste and errors. This approach improves both efficiency and effectiveness.

To stay competitive, you should identify processes needing improvement based on inefficiencies and stakeholder feedback. Setting clear objectives is important since it directs your optimization efforts toward measurable outcomes related to quality, time, and cost.

Furthermore, nurturing a culture of continuous optimization encourages adaptation and innovation in response to market demands. In the end, effective optimization initiatives can lead to significant financial savings by reducing execution time and costs through better resource allocation and minimized redundancies.

Steps for Effective Process Optimization

To achieve effective process optimization, you should start with a clear comprehension of your current workflows. Here’s how to get started:

- Map current processes to visualize workflows, identify bottlenecks, and understand task flow.

- Collect and analyze data using Key Performance Indicators (KPIs) to assess efficiency, focusing on metrics like cycle time and error rates.

- Identify pain points where inefficiencies occur, targeting areas that lead to delays, higher costs, or customer dissatisfaction.

- Set clear objectives that guide your optimization efforts, guaranteeing alignment with business strategies and stakeholder expectations.

After implementing changes based on your analysis, continuously monitor the new processes to verify they’re effective and to uncover further areas for improvement.

Process Mapping Techniques

When you use process mapping techniques, you create a visual representation of workflows that makes it easier to spot inefficiencies and bottlenecks.

For example, employing flowcharts can help you identify sequential tasks and decision points, whereas swimlane diagrams clarify responsibilities across different roles.

Visual Workflow Representation

Visual workflow representation, through process mapping techniques, plays a crucial role in helping organizations comprehend their current workflows. By visualizing processes, you can easily spot inefficiencies and areas needing improvement.

Here are some common process mapping methods you might consider:

- Flowcharts: Use standardized symbols like ovals for start/end points and rectangles for processes to improve clarity.

- Swimlane Diagrams: Categorize processes by department or role, which helps clarify responsibilities and promotes accountability.

- Value Stream Mapping: Focus on the flow of materials and information, allowing you to identify waste and streamline activities.

- Gantt Charts: Track project timelines and dependencies, ensuring everyone stays aligned with deadlines.

Employing these techniques can greatly enhance your comprehension of workflows and improve overall efficiency.

Identifying Process Bottlenecks

Identifying process bottlenecks is essential for enhancing operational efficiency, as these obstacles often hinder productivity and resource utilization.

Process mapping techniques, like flowcharts and swimlane diagrams, help you visualize workflows, making it easier to spot inefficiencies. By detailing the sequence of tasks and interactions, these tools clarify responsibilities and highlight specific pain points, such as delays or redundancies.

Engaging stakeholders during this mapping process guarantees you gather valuable insights from those executing the tasks daily. Furthermore, continuous monitoring of these process maps allows you to adapt quickly to new bottlenecks, maintaining improved efficiency over time.

Data Collection and Analysis Methods

Effective data collection and analysis methods are essential for optimizing processes within any organization. By employing various techniques, you can gain valuable insights into workflows and performance.

Consider these methods:

- Surveys and interviews: Gather qualitative insights from employees about their experiences.

- KPI dashboards: Use quantitative data to measure process efficiency and effectiveness.

- Process mining: Analyze event logs from IT systems to identify bottlenecks and inefficiencies.

- Statistical analysis: Apply techniques like regression analysis to uncover trends and areas for improvement.

Integrating data analytics software improves your ability to visualize this data, allowing you to make informed decisions based on thorough insights into process performance.

Make sure to choose the right methods that suit your organization’s specific needs.

Identifying Pain Points in Processes

To effectively identify pain points in your processes, start by analyzing any flaws that disrupt workflow.

Gathering performance metrics, like cycle times and error rates, can highlight areas that need attention.

Analyzing Process Flaws

When analyzing process flaws, it’s crucial to focus on identifying pain points that hinder efficiency and productivity.

To effectively pinpoint these issues, consider the following strategies:

- Review key performance indicators (KPIs) to detect high cycle times or increased error rates.

- Utilize process mapping to visualize workflows, helping to uncover bottlenecks or redundancies.

- Apply root cause analysis techniques to understand the underlying reasons for inefficiencies.

- Engage frontline employees in the evaluation process, as they possess valuable insights into daily workflow challenges.

Gathering Performance Metrics

Gathering performance metrics serves as an essential step in identifying pain points within business processes, as it allows you to quantify efficiency and effectiveness through key performance indicators (KPIs).

You should focus on metrics like cycle time, error rates, and resource utilization, which provide insights into how well processes are functioning. Analyzing historical data helps you uncover patterns and trends, revealing inefficiencies that need addressing.

Process mapping techniques can visually illustrate workflows, making it easier to identify bottlenecks hindering performance. By regularly collecting and reviewing these metrics, you can track progress over time, ensuring that your optimization efforts lead to concrete improvements.

Engaging stakeholders in this process encourages collaboration and improves comprehension of potential pain points.

Setting Clear Objectives for Optimization

How can you guarantee your process optimization efforts are truly effective? By setting clear objectives that guide your actions.

Start by defining SMART goals—specific, measurable, achievable, relevant, and time-bound—that align with your broader business objectives.

Here are some key points to contemplate:

- Involve key stakeholders to gather diverse perspectives, enhancing collaboration.

- Use data-driven insights from past performance metrics to inform your objectives.

- Ascertain your goals contribute to overall organizational success and competitive positioning.

- Regularly review and adjust these objectives based on ongoing monitoring and changing business needs.

Implementing Changes for Improvement

Implementing changes for improvement in your processes is essential for achieving optimization, as it directly addresses specific pain points and inefficiencies.

Start by identifying these issues through process mapping and data analysis, which will guide your targeted improvements. Set clear, measurable objectives to guarantee your changes align with desired outcomes, like reducing costs or improving service quality.

Incorporate automation and technology to increase efficiency, allowing for faster execution and minimizing error rates. Engage all relevant stakeholders during this change process to cultivate collaboration and reduce resistance, which raises the likelihood of successful implementation.

Monitoring and Measuring Results

To effectively monitor and measure results, you need to focus on Key Performance Indicators (KPIs) that align with your optimization goals.

By employing data analysis techniques, you can identify trends and areas needing improvement, ensuring that your processes remain efficient.

This structured approach not just supports a continuous improvement cycle but likewise helps you make informed decisions for future optimization efforts.

Key Performance Indicators

Key Performance Indicators (KPIs) serve as essential tools for organizations aiming to measure their success in achieving strategic objectives. By utilizing quantifiable metrics, you can evaluate and benchmark performance effectively.

To guarantee your KPIs are impactful, they should be:

- Specific: Clearly define what you’re measuring.

- Measurable: Use data that allows for quantification.

- Achievable: Set realistic targets based on available resources.

- Relevant: Align with your strategic goals and objectives.

Common KPIs in process optimization include cycle time, error rates, throughput, and customer satisfaction scores.

Regularly monitoring these indicators helps you identify trends, uncover inefficiencies, and make informed decisions to drive continuous improvement. A well-defined KPI framework promotes transparent communication among stakeholders, aligning efforts with your organization’s goals.

Data Analysis Techniques

Effective data analysis techniques are crucial for monitoring and measuring results in process optimization. You can use Key Performance Indicators (KPIs) to track metrics like cycle time, error rate, and throughput, ensuring you focus on relevant aspects of efficiency.

Process mining tools analyze event logs to visualize workflows, helping you spot inefficiencies that require attention. Employ statistical analysis methods, such as control charts and histograms, to assess process stability and variation, providing insights for improvement.

Benchmarking against industry standards allows you to measure performance and identify gaps. Finally, continuous monitoring through dashboards offers real-time insights, enabling you to make timely adjustments and maintain ideal performance levels throughout the optimization process.

Continuous Improvement Cycle

Monitoring and measuring results is essential in the Continuous Improvement Cycle, as it allows organizations to evaluate the effectiveness of their optimized processes.

By consistently tracking performance, you can guarantee that established performance indicators are met. Here are some key actions to take:

- Define and track Key Performance Indicators (KPIs) to offer quantifiable metrics.

- Review process performance data regularly to identify bottlenecks and areas for improvement.

- Engage stakeholders and frontline employees in the monitoring process for valuable insights.

- Utilize real-time data analytics tools to respond swiftly to changes and maintain efficiency.

These practices cultivate a culture of ongoing improvement, enabling you to sustain the benefits of process optimization over time.

Benefits of Process Optimization

Process optimization brings a multitude of benefits that can substantially impact an organization’s performance and profitability. By improving efficiency, you can reduce process execution time by up to 30% during lowering operational costs.

Eliminating waste and redundancies typically results in financial savings, contributing to a 10-20% increase in profit margins. Optimized workflows improve process quality, leading to a 25% reduction in errors and higher customer satisfaction rates.

Engaging in continuous process optimization can boost your competitive advantage, with 60% of companies reporting an improved market position because of more efficient operations.

Furthermore, cultivating a culture of continuous improvement encourages innovation, allowing employees to contribute ideas that elevate overall business performance, further driving success.

Challenges in Process Optimization

As organizations endeavor to improve their operations through process optimization, several challenges can impede progress. You might encounter the following issues that can hinder your efforts:

- Limited resources: Time and budget constraints can lead to incomplete or ineffective changes.

- Resistance to change: Employees may feel threatened by new processes, creating uncertainty about their roles.

- Leadership buy-in: Strong support from leadership is crucial; without it, the necessary culture of collaboration may not develop.

- Inadequate training: Employees may struggle to adapt to new processes without proper guidance, leading to ineffective implementation.

Addressing these challenges requires a strategic approach, focusing on clear communication, adequate training, and realistic expectations to guarantee successful process optimization initiatives.

Frequently Asked Questions

What Are the Steps in Process Optimization?

To optimize a process, start by mapping out the current workflows to spot inefficiencies.

Next, collect data and analyze it using Key Performance Indicators (KPIs) to identify specific pain points.

Set measurable objectives that align with your organization’s goals.

Then, implement changes, often incorporating automation to streamline tasks.

Finally, continuously monitor the new process to catch any emerging inefficiencies, ensuring ongoing improvement and effectiveness in achieving your objectives.

What Is the Meaning of Process Optimization?

Process optimization means improving business processes to improve efficiency, effectiveness, and quality. You focus on minimizing waste, reducing costs, and increasing throughput during meeting performance standards.

This involves analyzing current workflows, identifying bottlenecks, and implementing solutions. For instance, using process mapping tools helps visualize steps, whereas data analysis reveals areas for improvement.

In the end, effective process optimization promotes a culture of continuous improvement, ensuring better resource allocation and driving innovation within your organization.

What Are the Phases of the Optimization Process?

The optimization process consists of five key phases.

First, you’ll map the current process, identifying workflows and bottlenecks.

Next, you’ll collect and analyze data using Key Performance Indicators (KPIs) to assess performance.

Then, you’ll identify pain points that hinder efficiency.

After that, you’ll set clear objectives for improvement.

Finally, you’ll implement the changes, continuously monitoring results to guarantee they lead to the desired outcomes and improve overall process efficiency.

What Are the Steps You Perform for Optimization?

To optimize processes, start by mapping out your current workflows to spot inefficiencies.

Next, gather data and analyze it using Key Performance Indicators (KPIs) to evaluate performance.

Identify specific pain points that need attention, then set clear, measurable objectives that align with your business goals.

Implement the necessary changes based on your findings, and monitor the results closely to guarantee the optimized processes achieve the desired outcomes effectively.

Conclusion

In summary, mastering process optimization is crucial for any organization looking to improve efficiency and reduce waste. By systematically analyzing processes through techniques like mapping and root-cause analysis, you can identify areas for improvement. Implementing changes and continuously monitoring results guarantees that your operations remain effective and aligned with business goals. In the end, embracing process optimization not just boosts productivity but additionally improves customer satisfaction, allowing your organization to thrive in a competitive environment.

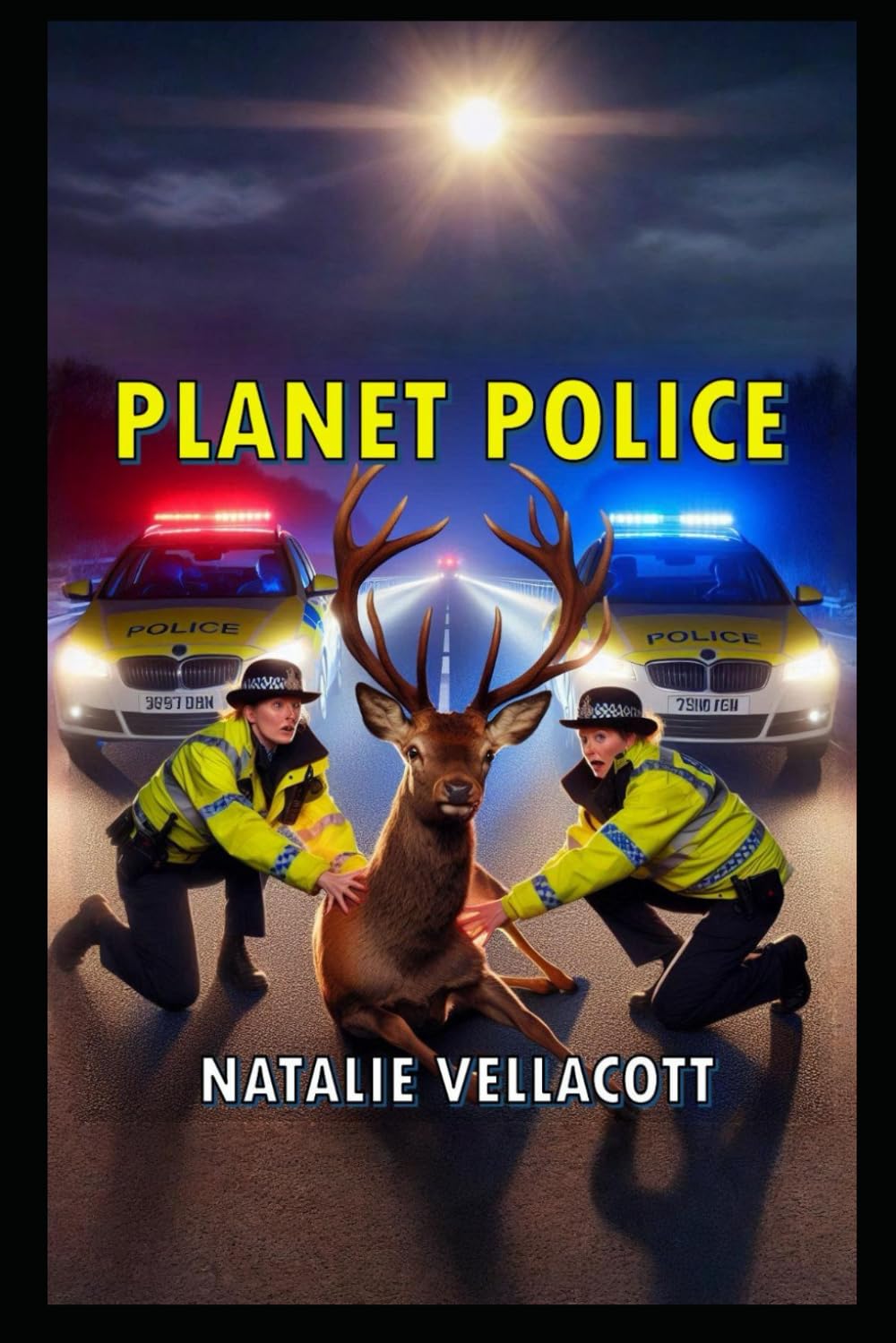

Image Via Envato