Warehousing order and fulfillment are essential processes in modern supply chain management, focusing on how products are stored, managed, and delivered to customers. Warehousing involves the long-term storage of inventory, whereas fulfillment centers emphasize quick order processing and shipping. Comprehending these functions helps businesses optimize their inventory levels and meet customer demands efficiently. As you explore this topic further, you’ll uncover key differences and strategies that can improve operational effectiveness and customer satisfaction.

Key Takeaways

![]()

- Warehousing focuses on long-term storage of bulk inventory, while fulfillment centers prioritize quick order processing and shipping to consumers.

- Fulfillment centers handle the entire order process, including receiving, picking, packing, and shipping, unlike static warehouses.

- Effective inventory management in fulfillment centers enhances order fulfillment efficiency and reduces stockouts compared to traditional warehousing.

- Outsourcing fulfillment can optimize costs, improve scalability, and allow businesses to concentrate on core operations like marketing and product development.

- Streamlined order fulfillment through fulfillment centers enhances customer experience by reducing delivery times and minimizing errors in order processing.

Understanding Warehousing and Fulfillment Solutions

What do you really need to know about warehousing and fulfillment solutions? Comprehending the difference between a fulfillment center and a warehouse is vital for your business.

Warehousing primarily focuses on long-term storage, designed for bulk inventory management, whereas fulfillment centers emphasize quick order processing and shipping directly to consumers.

Fulfillment centers handle the entire order process, including receiving, picking, packing, and shipping, which allows for rapid inventory turnover.

You can choose to manage these operations in-house or partner with third-party logistics (3PL) providers, often leading to improved efficiency and lower costs.

Effective inventory management in both settings helps you avoid stockouts and overstock situations, optimizing your storage space and retrieval processes for better overall performance.

Key Differences Between Fulfillment Centers and Warehouses

When you compare fulfillment centers and warehouses, you’ll notice key differences in their functions and purposes.

Fulfillment centers focus on quick inventory turnover and efficient order processing, whereas warehouses primarily serve as long-term storage for bulk items.

Comprehending these differences, including shipping practices and operational flexibility, can help you choose the right solution for your business needs.

Storage vs. Turnover

Although both fulfillment centers and warehouses play vital roles in the supply chain, they serve distinct purposes that greatly impact inventory management and order processing.

Fulfillment centers focus on rapid inventory turnover, emphasizing quick processing and shipping of individual customer orders. Conversely, warehouses primarily serve as long-term storage facilities for bulk inventory, engaging in static operations with minimal movement of goods.

While fulfillment centers actively manage inventory to improve order fulfillment efficiency, warehouses concentrate on maintaining large inventories for extended periods.

Shipping practices also differ; fulfillment centers require frequent pickups by shipping carriers for timely distribution, whereas warehouses often schedule pickups less frequently to minimize costs.

Comprehending these differences is fundamental for optimizing your supply chain strategy.

Operational Functions Comparison

Comprehending the operational functions of fulfillment centers and warehouses is key to optimizing your supply chain. As warehouses mainly serve as storage facilities for long-term inventory, fulfillment centers focus on fast turnover, efficiently picking, packing, and shipping individual orders. Unlike warehouses, fulfillment centers engage in complex logistics operations, utilizing advanced technologies for rapid order fulfillment.

| Feature | Fulfillment Center | Warehouse |

|---|---|---|

| Primary Function | Order processing | Inventory storage |

| Operations Activity | Highly active | Minimal |

| Shipping Frequency | Frequent pickups | Scheduled, less frequent |

Understanding these key differences between a distribution center vs fulfillment center can greatly impact your operational efficiency and customer satisfaction.

Shipping Practices Differences

Grasping the distinctions in shipping practices between fulfillment centers and warehouses is crucial for optimizing your logistics strategy.

Fulfillment centers prioritize rapid inventory turnover, requiring frequent carrier pickups to guarantee timely delivery, whereas warehouses typically have scheduled, less frequent pickups for cost-effective shipping.

In fulfillment centers, the focus is on dynamic order processing, including picking, packing, and shipping directly to consumers.

Conversely, warehouses mainly handle long-term storage and bulk orders.

Fulfillment centers efficiently manage high-volume orders and returns, leveraging advanced logistics technology for real-time inventory tracking.

This contrasts with warehouses, which often rely on traditional inventory systems and slower, more methodical shipping processes.

Comprehending these differences in warehousing and fulfillment services can greatly impact your operational efficiency.

The Importance of a Strategic Warehousing Fulfillment Strategy

A strategic warehousing fulfillment strategy is essential for effective inventory management and ensuring your products are always available when customers need them.

By selecting the right location for your warehouse, you can considerably cut shipping costs and improve delivery times, which directly boosts customer satisfaction.

Furthermore, implementing cost optimization strategies will help you manage expenses and adapt to seasonal fluctuations, in the end supporting your business’s growth.

Effective Inventory Management

Effective inventory management plays a pivotal role in optimizing warehousing operations, especially when space and retrieval processes are considered. A cluttered environment can lead to stockouts and under-utilized inventory, negatively impacting your fulfillment efficiency.

By implementing a strategic warehousing fulfillment strategy, you can scale operations during order volume spikes without sacrificing performance or incurring high storage costs. Furthermore, fluctuating storage costs can strain your budget, making it crucial to adopt a customized approach to inventory management.

Utilizing automation technology improves efficiency and accuracy, allowing you to meet customer demands effectively. In the end, effective inventory management guarantees that your warehousing and fulfillment processes run smoothly, lowering operational costs while enhancing service levels in a competitive market.

Strategic Location Selection

Selecting the right location for your warehouse can greatly influence your overall fulfillment strategy.

Strategic location selection is crucial for effective warehousing and order fulfillment, as it directly impacts shipping costs and delivery speed. By positioning your warehouse closer to key markets, you can reduce transit times and lower expenses.

Furthermore, a well-planned fulfillment strategy optimizes inventory turnover, ensuring high-demand products are stored near target customers for quicker order fulfillment.

Consider factors like labor availability, infrastructure, and market access, as these can affect operational costs and service levels.

An effective location strategy also enables your business to scale operations during peak seasons, meeting fluctuating customer demands without incurring excessive storage costs.

Cost Optimization Strategies

When you prioritize cost optimization in your warehousing fulfillment strategy, you’re not just improving your bottom line; you’re enhancing your overall operational efficiency.

Effective inventory management is essential, as utilizing space well reduces clutter and prevents stockouts, ensuring products are available for customers.

The location of your distribution and fulfillment centers greatly impacts shipping costs and delivery speed, with strategically placed warehouses potentially cutting transportation expenses by 30%.

Implementing a flexible warehousing strategy helps manage storage needs, mitigating excessive fees during off-peak periods.

Furthermore, outsourcing fulfillment to third-party logistics providers (3PLs) can streamline operations, often leading to cost reductions of 10-20%.

A well-planned strategy additionally allows you to scale operations efficiently without incurring high long-term lease costs.

Challenges of Managing Warehouse Space

Managing warehouse space presents several challenges that can affect your overall operational efficiency. Long-term leases can limit your flexibility, making it tough to adapt to demand fluctuations or unexpected growth.

Finding suitable warehouse center space is increasingly difficult because of high demand and specific storage needs, which can delay scaling operations. Cluttered environments often lead to under-utilized inventory and stockouts, emphasizing the need for effective inventory management.

Furthermore, storage costs can surge during peak seasons, straining your budget, whereas off-peak periods may still incur excessive charges. Searching for extra warehouse space often brings higher costs and logistical hurdles, especially when accommodating special storage requirements or ensuring regulatory compliance.

Addressing these challenges is vital for maintaining a streamlined operation.

Benefits of Outsourcing Fulfillment

Outsourcing fulfillment to third-party logistics (3PL) providers offers numerous advantages that can greatly benefit your business operations.

By partnering with warehousing and fulfillment companies, you can achieve significant cost reductions, as you’ll save on staffing, warehousing, and shipping expenses. This allows you to focus on core activities like product development and marketing as you leave logistics to experts.

In addition, a strategic partnership provides scalability, enabling you to adjust operations based on fluctuating order volumes without long-term leases or excess storage costs.

Utilizing fulfillment centers also leads to faster order processing and shipping, enhancing accuracy and reducing delivery times.

In the end, outsourcing fulfillment can improve customer satisfaction by ensuring reliable inventory management and timely deliveries, keeping your business competitive in the e-commerce environment.

How Fulfillment Centers Enhance Customer Experience

Fulfillment centers play a crucial role in enhancing the customer experience by streamlining the entire order fulfillment process. They efficiently pick, pack, and ship products, markedly reducing delivery times and boosting customer satisfaction.

Utilizing advanced technology like AI and machine learning, these centers optimize inventory management and guarantee accurate order processing, leading to fewer errors. Many fulfillment centers additionally offer customized packaging solutions, enhancing branding and providing a better unboxing experience, which cultivates customer loyalty.

Case Studies of Successful Fulfillment Partnerships

When businesses seek to improve their logistics capabilities, partnering with a fulfillment center can yield significant benefits, as demonstrated by various successful case studies.

For instance, Taste Salud scaled from $0 to $20 million in revenue within three years by leveraging ShipBob‘s warehousing and shipping services. Our Place saved $1.5 million on freight costs and reduced shipping times by half through the same network.

Furthermore, Peak and Valley improved their B2B fulfillment and compliance using ShipBob’s EDI solution, illustrating how technology can streamline operations.

Many businesses shift to fulfillment partners after handling logistics themselves, leading to notable improvements.

These case studies reveal that strategic locations and expertise in logistics management can optimize inventory turnover and boost customer satisfaction effectively.

Frequently Asked Questions

What Is Warehousing and Fulfillment Services?

Warehousing and fulfillment services are crucial for managing inventory and order processing.

Warehousing involves storing goods until they’re needed, whereas fulfillment encompasses receiving, processing, packaging, and shipping orders to customers.

Fulfillment centers prioritize quick order turnaround and often utilize third-party logistics providers to handle high volumes efficiently.

What’s the Difference Between Warehouse and Fulfillment?

The difference between a warehouse and a fulfillment center lies in their functions. A warehouse primarily stores inventory, with limited movement and minimal operations.

Conversely, a fulfillment center actively processes orders, focusing on picking, packing, and shipping directly to customers. Fulfillment centers emphasize quick order turnaround, often utilizing advanced technologies, whereas warehouses maintain static inventory and are geared toward cost-efficient storage.

Comprehending these distinctions can help you choose the right solution for your business needs.

What Is Order Fulfillment in a Warehouse?

Order fulfillment in a warehouse involves several key steps.

You receive inventory, process customer orders, and pick items from storage.

Once you’ve gathered the products, you pack them securely for shipment.

Accurate inventory management is essential to prevent stockouts or excess stock, ensuring you meet customer demands efficiently.

What Is a Warehousing Order?

A warehousing order is a set of instructions that guides how inventory is stored and managed in a warehouse. It specifies details like SKU numbers, quantities, and designated storage locations, ensuring proper organization.

You need to process these orders efficiently to maintain ideal inventory levels and prevent stockouts. By using inventory management systems, you can track goods, perform accurate stock counts, and generate reports that support effective decision-making in your operations.

Conclusion

In conclusion, comprehending warehousing order and fulfillment is crucial for optimizing inventory management and improving customer satisfaction. By distinguishing between fulfillment centers and traditional warehouses, you can develop a strategic approach that addresses your business needs. Overcoming challenges in warehouse space management and exploring the benefits of outsourcing fulfillment can improve operational efficiency. In the end, effective fulfillment processes lead to a better customer experience, ensuring that your products reach consumers swiftly and accurately, which is critical for business success.

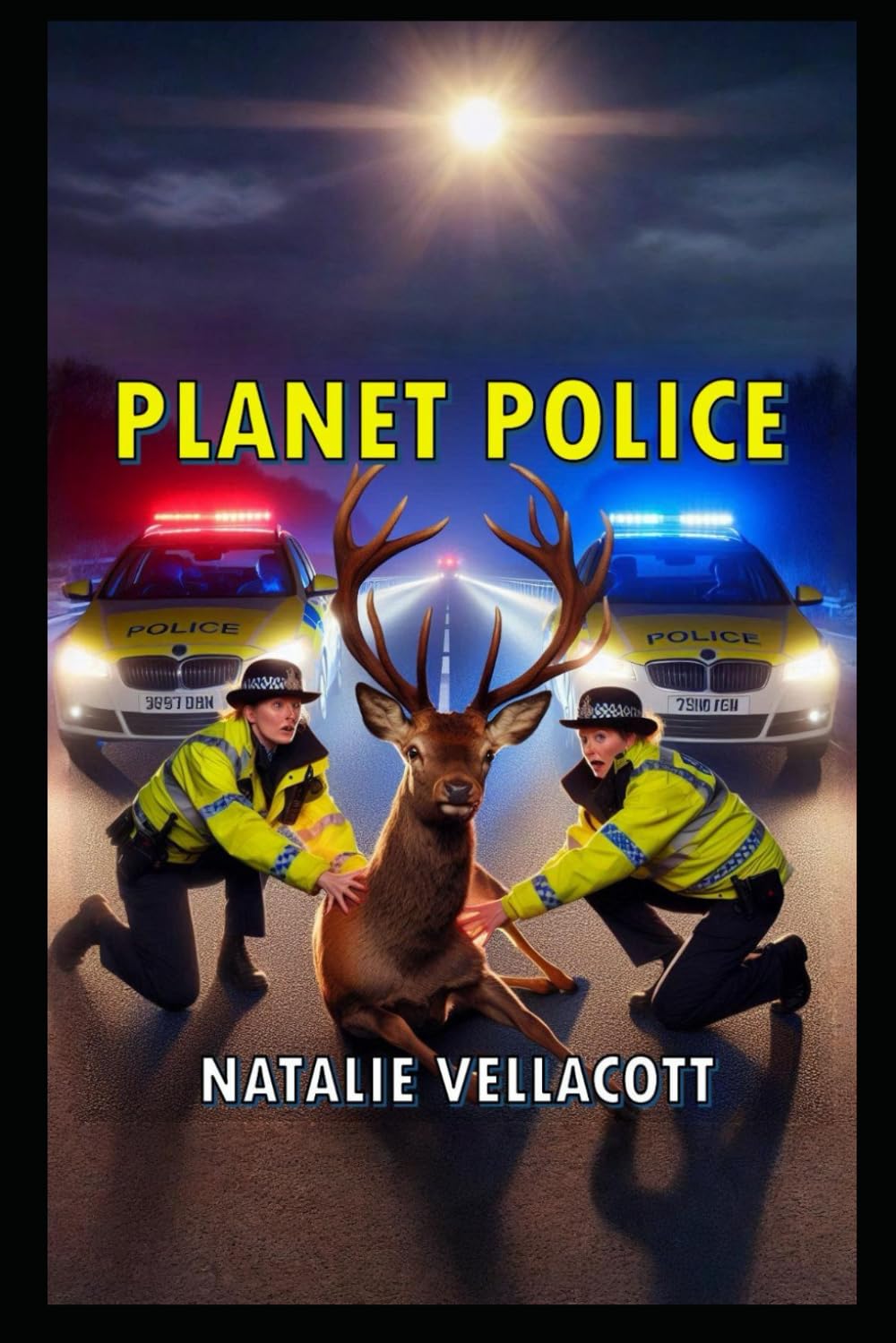

Image Via Envato